3D Print faster and better

We designed a print head for fused deposition modeling 3d printers. Actively adjusting the aperture of the printer nozzle during printing facilitates faster high resolution printing. Our design was inspired by the muscles in the human eye.

This project was undertaken as part of the bio-inspired engineering class EMEC 465 at Montana State University. The project team was: Christen Barringer, Atticus Cummings, Kyle Kramer, and Sydney Ross. Our professor/faculty advisor was Dr. Corey Pew.

Analysis of print times using Pursa slicing software supported the hypothesis that the variable diameter nozzle could reduce print times. Additional analysis suggests that a variable diameter nozzle could maintain the same resolution as standard print heads while reducing print time. While cost and manufacturability would initially affect adoption and the potential number of applications that benefit from variable diameter nozzles, this technology could prove useful to industries where a faster print time is an imperative.

A better print head inspired by nature

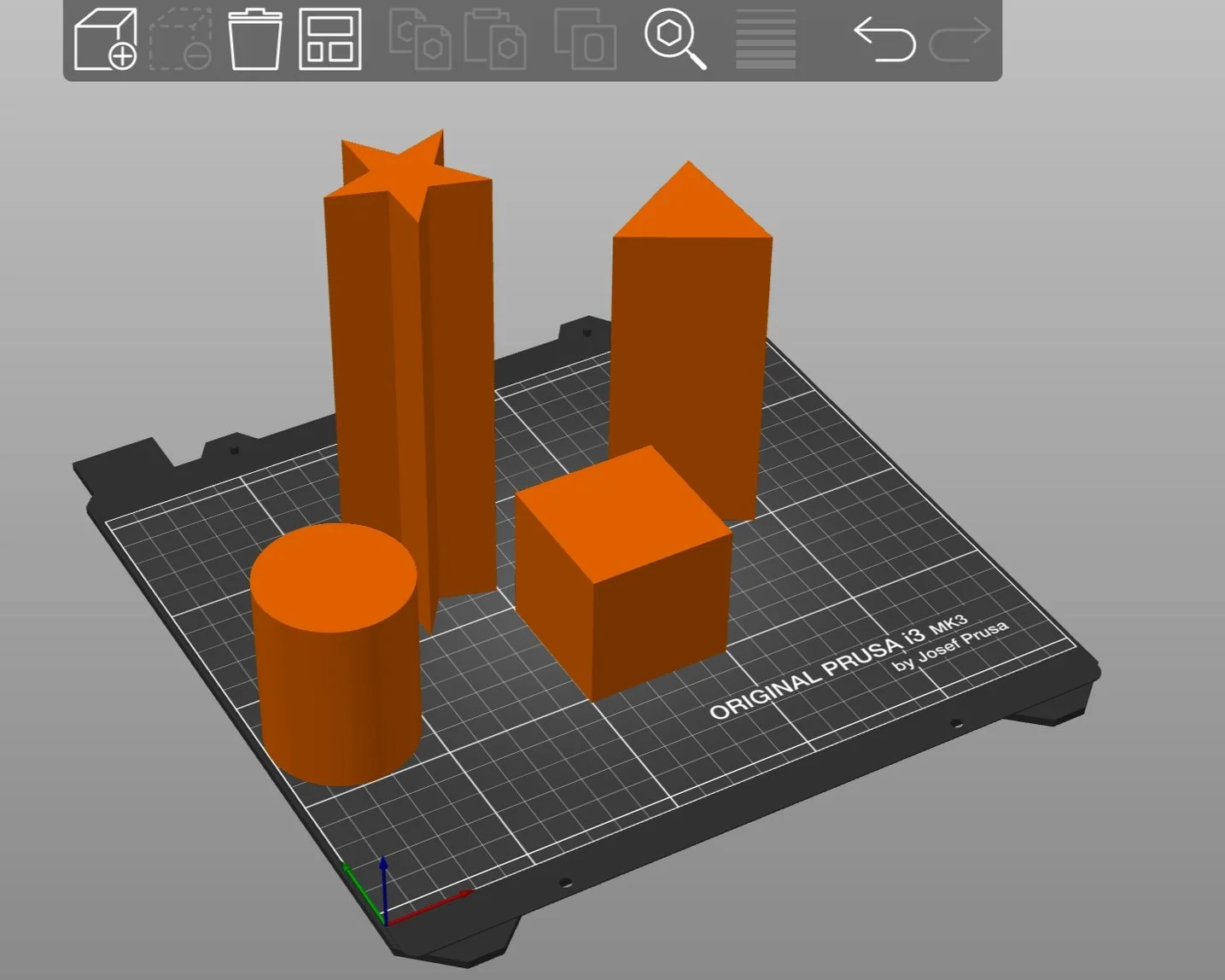

Shapes with a variety of surface area to volume ratios were analyzed for print speed using small and large aperture print heads to determine how much a variable aperture print head would increase speed.